General Electric

DMEnergy company offers a wide range of equipment and maintenance services to meet the most challenging requirements. Contact us and our specialist will help you to find the best solution to satisfy your energy and budget requirements.

General Electric is one of the world's largest companies in the energy sector. The company manufactures efficient and reliable heavy-duty and aeroderivative gas turbines with output ranging from 34 MW to 571 MW. Its customers take advantage of the latest scientific achievements to increase their own production capacity, while having a minimal destructive impact on the environment.

Today, General Electric is engaged in the supply of power equipment, as well as its maintenance, repair and other services.

GENERAL OVERVIEW

General Electric’s efficient and reliable aeroderivative and heavy duty gas turbines deliver operational flexibility and performance required to adapt to a rapidly developing power generation environment. Gas turbine products with output ranging from 22 MW to 519 MW provide a reliable and efficient solution to deliver the power needed by utility power generators, industrial operators, and communities. You can count on gas turbines by General Electric even in remote locations and harsh conditions.

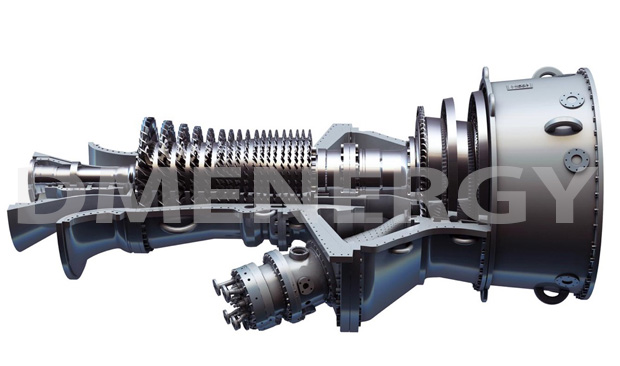

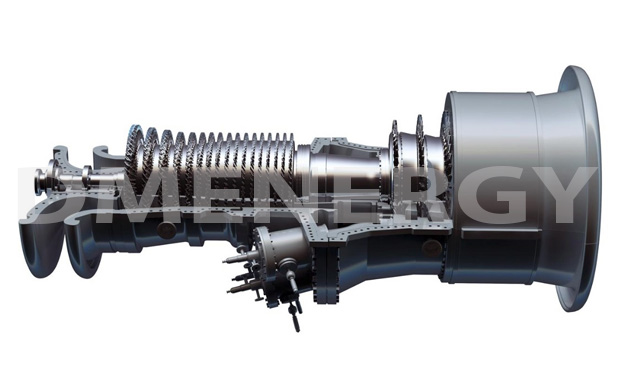

All GE’s gas turbines based on jet engine technology introduced by General Electric in the first half of the 20th century. They are generally subdivided into heavy duty (also called “frame”) or aeroderivative gas turbines. Contemporary turbines sometimes adopt features of both types. In general, the differences between these two categories of gas turbines are size, weight, combustor type, and turbine design. Heavy duty gas turbines are usually field constructed and maintained at site, whereas aeroderivative gas turbines are designed to allow for easy and quick replacement of the entire engine when maintenance is required.

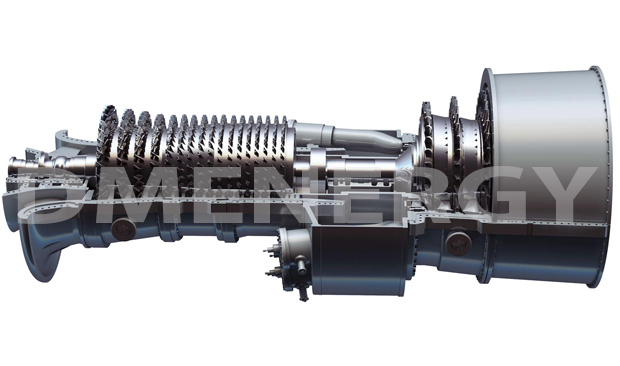

AERODERIVATIVE TURBINES

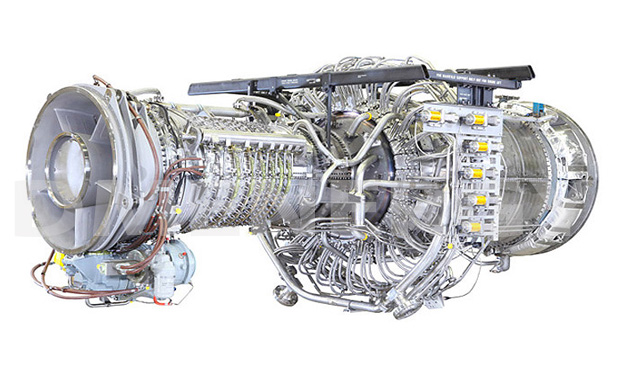

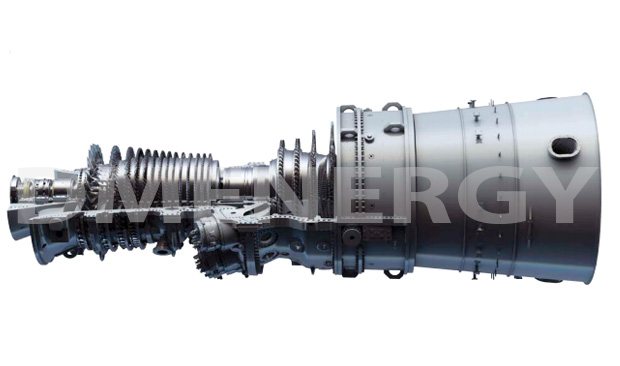

GE LM2500 (50 Hz)

LM2500 series gas turbines are designed for various applications in the oil and gas and industrial segments with a output from 22 MW to 33 MW in a simple operation cycle. The product family includes LM2500, LM2500+ and LM2500+G4 units. LM2500 has gain a reputation as the most durable industrial gas turbine generator in its class. LM2500 family can be applied for onshore and offshore mechanical drive, in-plant power generation, pipelines, platforms, cogeneration and combined cycles, it continues to evolve and deliver increased consumer value.

- Easy installation and ease of maintenance due to lightweight and compact design

- Reliable design

- Fast startup (<10 minutes) and ability to operate in highly cyclical environments.

- Dual fuel capability for distillate and natural gas.

- Can accommodate naphtha, propane, coke oven gas, ethanol, and LNG.

- Reduced NOx (<15 ppm) with the DLE combustor.

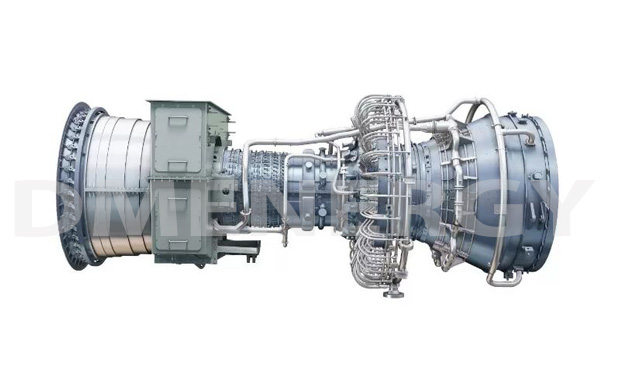

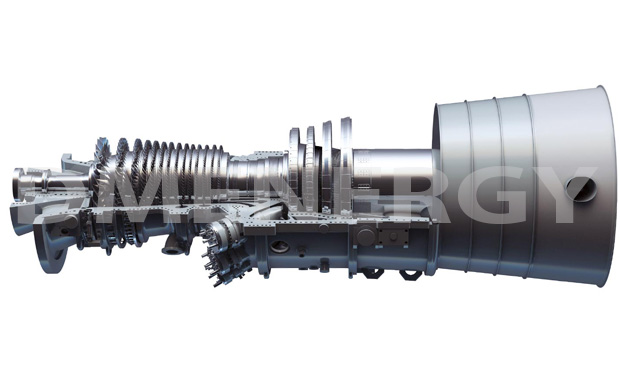

GE LM6000 (50 Hz)

GE LM6000 family of aeroderivative gas turbines has reached 31 million operating hours with more than 1,100 units shipped worldwide. Reliable and efficient LM6000 aeroderivative gas turbine with cycle output from 49 MW to 57 MW can be adapted to meet the unique operational requirements of virtually any distributed power application. Fuel flexibility is crucial for isolated installations with black start requirements, and the variety of combustion technologies helps operators meet strict CO2 and NOx emission requirements.

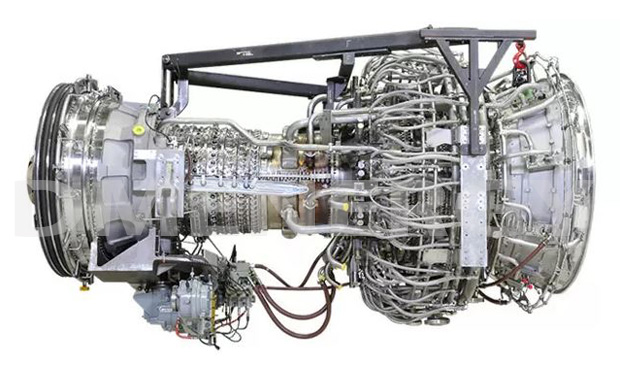

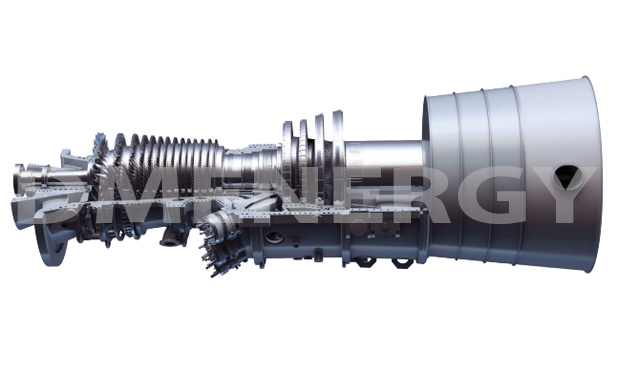

TM2500 MOBILE GAS TURBINE-GENERATOR SET (50 Hz)

TM2500 uses the highly successful LM2500+G4 aeroderivative gas turbine to solve a number of industry challenges by positioning power at or near the point of use. Known as a "power plant on wheels”, the TM2500 generator set is ideal for providing a baseload bridge to permanent power plants or for generating backup power in support of disaster management, power plant shutdowns, power grid instability due to the introduction of renewable energy sources, or equipment maintenance.

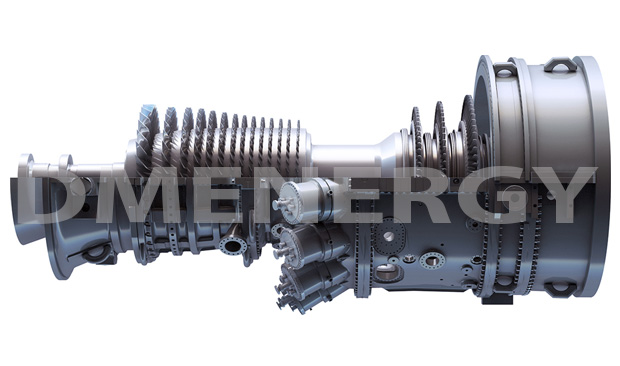

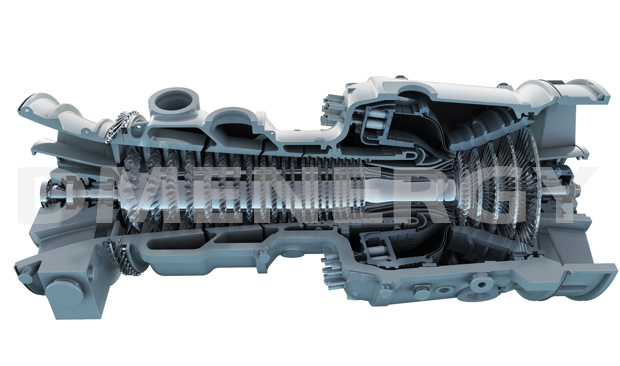

LMS100 GAS TURBINE (50 Hz)

In order to meet the ever-changing operational needs of the modern energy industry around the world, power producers are looking for the most flexible, efficient and reliable technologies. GE’s LMS100 intercooled gas turbine system guarantees fast start-up, efficient cycle and power control capability, as well as a simple cycle with a thermal efficiency of more than 43 percent and emissions that meet strict requirements. LMS100-PA+/PB+ gas turbines provide power from 105 MW to 111 MW with water injection or dry low emission (DLE) for NOx control. The LMS100 fleet consisting of more than 53 gas turbine generator sets reached 99.7 percent reliability with more than 400,000 hours of operation.

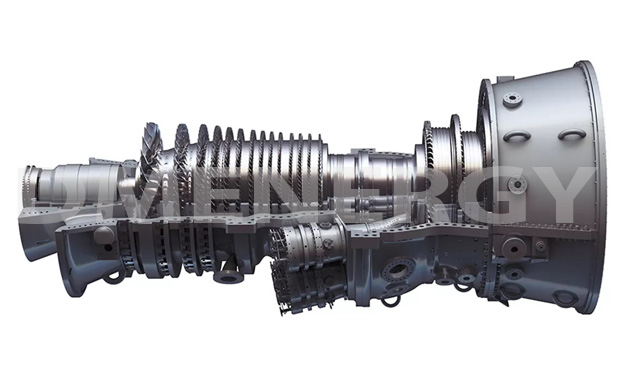

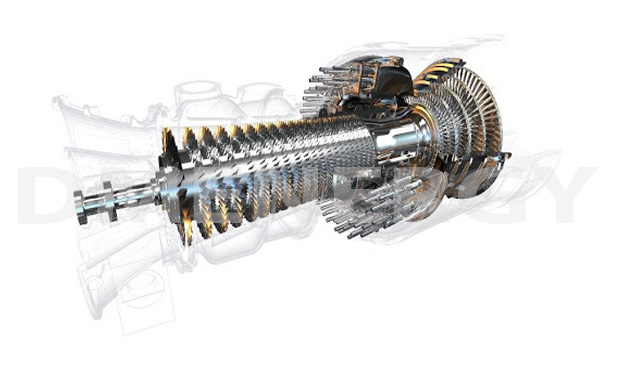

INDUSTRIAL TURBINES

FRAME 6

6F.01 GAS TURBINE (50 Hz)

F-class

GE 6F. 01 gas turbine is based on our 6C technology, which was introduced to the market almost 15 years ago and is successfully used in the industry. Thanks to proven technological updates and improvements, 6F.01 turbine is currently able to reach almost 57 percent efficiency in cogeneration operation. Its segment-leading exhaust energy supports flexible and cost-effective solutions for combined cycle power generation or cogeneration. There are options of cold-end or hot-end drive configurations. The 6F. 01 unit provides new solutions for installation or retrofitting of installations that can be customized for a specific application.

6F.03 GAS TURBINE (50 Hz)

F-class

6F.03 heavy-duty gas turbine, which can operate in a simple or combined cycle, provides a high level of efficiency, flexibility and reliability, regardless of whether there is a need to generate electricity on site or generate steam for petrochemical or centralized heat operations. The high exhaust energy and efficiency of multiple combustion systems make the 6F.03 gas turbine ideal for 50 Hz or 60 Hz medium-size applications. When operating off-grid, the 6F.03 units provide adequate power density with proven island mode characteristics and improved grid transient response capabilities.

6B.03 GAS TURBINE (50 Hz)

E-class

The reliable, robust 6b.03 heavy-duty gas turbine is undoubtedly one of GE's most popular turbines, especially for oil refineries, natural gas liquefaction industries, combined heat and power plants (CHP), and industrial power plants. The ability of this turbine to operate in island mode together with 94.6% availability allows the 6b.03 gas turbine to be an ideal choice for remote installations and extreme operating conditions away from the grid. With 99 percent reliability, proven and tested with more than 55 million hours of operation, GE 6B. 03 gas turbines provide the cost-effectiveness and high performance that manufacturers can count on.

7HA.01/.02 GAS TURBINES (60 Hz)

H-class

GE 7HA high-performance air-cooled gas turbine is considered the undisputed industry leader. The customer can choose from two models: the 7HA.01 turbine with a capacity of 280 MW and the 7HA.02 turbine with a capacity of 346 MW. The advantages of the 7HA.01 turbine are an additional capacity of 5 MW and a higher heat output of 60 BTU / kWh, compared to the 2015 production figures. Similarly, the 7HA.02 turbines now provide an additional heat output of 9 MW and 130 BTU/kWh of heat output. The simplified air-cooled architecture, use of advanced materials, high performance and reliability allow the 7HA turbine to guarantee low life cycle costs per megawatt for 60 Hz applications. With a high power density and a combined cycle efficiency of 62%, this gas turbine can efficiently convert fuel into electricity, helping to meet the growing demand for electricity.

7F.04 GAS TURBINE (60 Hz)

F-class

GE 7F. 04 is becoming the largest 60 Hz F-class fleet in the world fast enough. 7F. 04 guarantees reliability at the level of international standards and at the same time cost-effectiveness. In addition, its fuel flexibility is second to none. These plants run on natural gas, distillate, and crude oil. Machines that run on gas with high ethane content are also produced. Today, GE has installed more than 1,100 F-class turbines worldwide, generating 260 GW of electricity in 58 countries. The level of reliability is 99%, so customers get five to six days of work per year more than the average for the relevant industry. A 10-minute quick start allows you to increase revenue and dispatchability during high demand levels.

7F.05 GAS TURBINE (60 Hz)

F-class

GE 7F. 05 gas turbine was designed to increase the standard of flexibility and total efficiency of the F-class. 7F.05 turbine continues to be upgraded and improved, the base of installed models continues to grow and exceeds 20,000 hours of operation. The advantages of this flexible and fast-reacting 7F.05 turbine are the ability to run on natural gas, distillate oil and crude oil, fast start-up of 200 MW in ten minutes and a ramp rate of 40 MW per minute. The new standard in combustion technology introduced by this unit provides less than 5 ppm NOx emission at rated baseload while providing world-class efficiency. Where peak power is a key factor, the 7F.05 turbine guarantees reliable power up to 241 MW.

7F.06 GAS TURBINE (60 Hz)

F-class

The lowest life cycle cost while meeting the required project size is the main demand for gas turbines. The latest development of the GE 60 Hz family, 7F.06 gas turbine is capable of delivering higher performance and efficiency than any other 60 Hz F-class gas turbine, while maintaining NOx and CO emission rate of 9 ppm. The unique balance of performance and flexibility with a simple cycle base load of 270 MW and more than 41% efficiency, combined with the ability to quickly start a full load gas turbine in 10 minutes and a fast ramp capacity of 50 MW per minute-these are the advantages of this turbine. Therefore, 7F.06 gas turbine is capable of providing greater flexibility, including support for renewable energy sources. When operating in a combined cycle, 7F.06 gas turbine's power output advantage and efficiency of more than 60 percent provide the lowest cost of electricity in F-class 60 Hz technology.

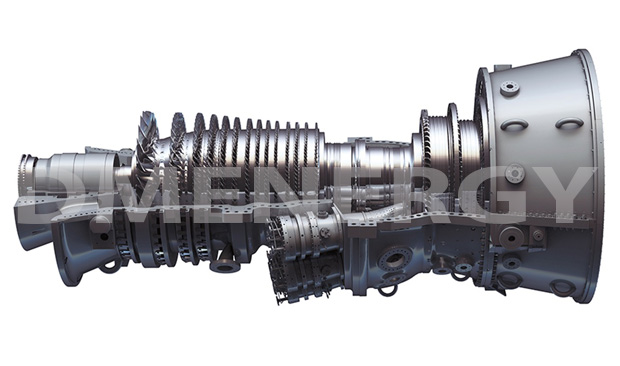

FRAME 9

9HA.01/.02 GAS TURBINES (50 Hz)

H-class

The undisputed industry leader - the highly efficient 9HA air-cooled gas turbine - available in two available versions-the 429 MW model 9HA.01 and the 519 MW model 9HA.02. Simplified air-cooled design, the use of advanced materials, and excellent performance and reliability allow GE 9HA units to provide an exceptionally low life cycle cost per megawatt. A high-density gas turbine together with a combined cycle efficiency of almost 63 percent provides an economical conversion of fuel to electricity thus helping to meet the increasingly dynamic demand for electricity.

9F.05 GAS TURBINE (50 Hz)

F-class

9F.05 gas turbine is designed to meet the demand for cleaner, reliable and economically efficient power in a 299 MW simple cycle package. With a fleet of more than 50 units and 800,000 hours of operation, the 9F.05 turbine is a proven performer with a combined cycle efficiency of over 60 percent and operational reliability of over 99 percent. The advantages of these aggregates are as follows: extended maintenance intervals, flexible fuel delivery, low NOx emissions, low CO emissions, and fast start-up.

9F.06 GAS TURBINE (50 Hz)

F-class

The new 9F. 06 gas turbine provides the highest possible performance and efficiency compared to any other GE F-class gas turbine. Advantages of this turbine: a unique balance of performance and flexibility with a baseload simple cycle rating of 342 MW and more than 41% efficiency, combined with a fast ramp capacity of 65 MW per minute. The 9F.06 turbine offers greater flexibility, including support for renewable energy sources. When operating in a combined cycle, the efficiency of 9F.06 gas turbine reaches over 61 percent and provides the lowest cost of electricity in 50 Hz F-class technology.

9E.03/.04 GAS TURBINES (50 Hz)

E-class

The reliable GE 9E.03 heavy-duty gas turbine provides the necessary power and is capable of operating in a huge number of operating cycles and applications in both the tropics and Arctic frosts. This is one of the most fuel-flexible products in the industry, providing the ability to use more than 50 types of fuel, i.e. almost the entire fuel spectrum. The 9E.04 heavy-duty gas turbine guarantees increased power and performance while maintaining the simplicity and operational advantages of the 9E.03 gas turbine. The result is a platform that provides high availability, reliability, and durability while simultaneously reducing the total cost of a kilowatt.

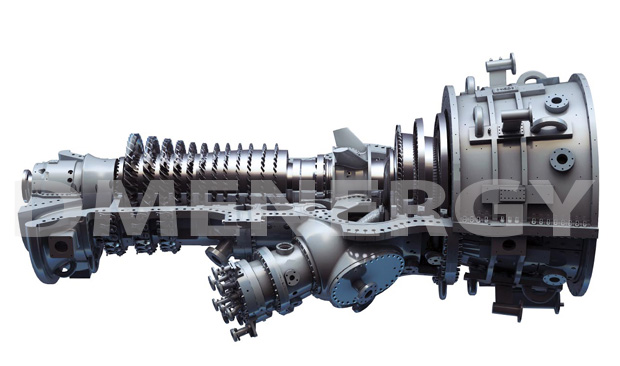

GT13E2 GAS TURBINE (50 Hz)

E-class

GE GT13E2 gas turbine is a leader in the E-class segment and provides excellent performance in a wide range of applications. There are two options - GT13E2 2012 and GT13E2 2005, which allows you to choose the gas turbine that best suits your technological needs. Not only can you choose the turbine configuration that meets your site-specific performance requirements, but you can also switch online between two operating modes: the first mode optimizes performance, and the other significantly extends standard maintenance intervals. This allows you to save money, allowing you to quickly respond to fluctuations in electricity demand while keeping costs at the required level.

ALSTOM

E-class

GT13E2, 2005 and GT13E2, 2012

GE GT13E2 gas turbine is a leader in the E-class segment and provides excellent performance in a wide range of applications. There are two options - GT13E2 2012 and GT13E2 2005, which allows you to choose the gas turbine that best suits your technological needs. Not only can you choose the turbine configuration that meets your site-specific performance requirements, but you can also switch online between two operating modes: the first mode optimizes performance, and the other significantly extends standard maintenance intervals. This allows you to save money, allowing you to quickly respond to fluctuations in electricity demand while keeping costs at the required level.